|

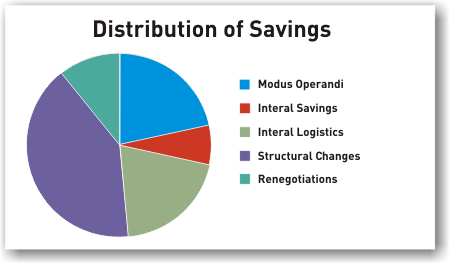

Logistics costs are more than just transport costs While other consultant companies focus mainly on transport costs and the shipping agreements that govern them, Prestandum looks at the big picture. We call this the Prestandum Method, and it involves scrutinizing the company’s total logistics costs. It is the company’s costs as a whole that must be optimized – not each individual cost on its own. If you only look at individual parts of this whole, a savings made in one area can re-emerge in another. Experience has shown us that the total cost reduction is usually distributed as shown in the chart below. |

|

|

Savings distribution patterns in Supply Chain projects |

|

The most significant savings are achieved through structural changes. Structural changes means that you do things differently than you do now, by rationalizing to eliminate operations or transports, for example. Changing a company’s Modus Operandi can also lead to significant savings. In most cases, this means that you decide how your company will organize its sales, and you do this by defining your customer promise and deciding which services you will charge for – and how. Considerable savings can also be achieved within internal logistics by rationalizing to eliminate unnecessary internal handling within the company. Rationalizations in the company’s terminal and warehouse are typical examples of this. Renegotiating shipping and terminal agreements typically only achieves about 10% of total potential savings. Most Supply Chain projects focus only on renegotiation, thereby missing out on considerable potential savings. |